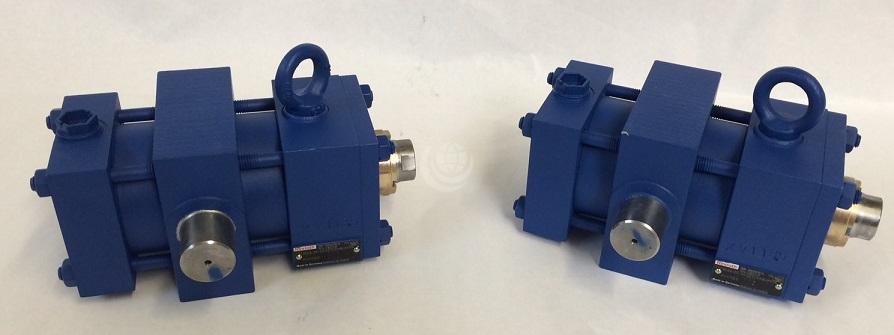

Welded Hydraulic Cylinders

So, we think we know why you’re here... You’re looking for welded hydraulic cylinders, right? Well, whether you are looking for a relatively “standard”, or completely bespoke welded hydraulic cylinders, you can rest assured knowing that, with over 75 years’ technical...