Rayco Stump Cutter Uses Parker Pump and Motor Combination

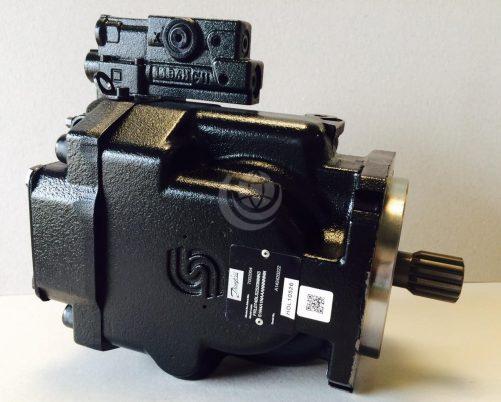

Following new, more stringent Tier IV diesel engine emissions regulations, Rayco, an environmental equipment designer for the tree care and landscape industries, took the opportunity to develop a more efficient, powerful and compact stump cutter, the RG165T-R. In comparison to previous...