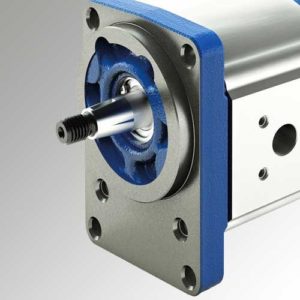

We offer the widest selection of hydraulic pumps in the UK, from leading and niche manufacturers around the world.

Hydraulic pumps play a vital role in your hydraulic system and machinery. Choosing the right pump can ultimately save you a lot of money by preventing potential malfunctions and costly operational downtime.

We’re confident we can find the pump that is right for you or that you’re looking for. We can assist you in purchasing new units, or if your existing hydraulic pump is now obsolete, we can help you source a direct equivalent.

We also offer a hydraulic pump repair service. Our repaired and refurbished hydraulic pumps are virtually indistinguishable to a brand new unit. As part of our service, we strip and assess the pump and provide a free of charge quote. In addition to pump repairs, we also repair and supply hydraulic cylinders, hydraulic motors and hydraulic power packs.

Our technical sales engineers are happy to provide in-depth technical data on all the equipment that we supply. This ensures that you can choose the perfect model for your system.

We only show a small selection of the products that we supply. For personal service and advice on any hydraulic part, please do not hesitate to contact our friendly team.

![]() Selecting hydraulic fluid for your hydraulic pump.

Selecting hydraulic fluid for your hydraulic pump.

READ THE BLOG >>

-

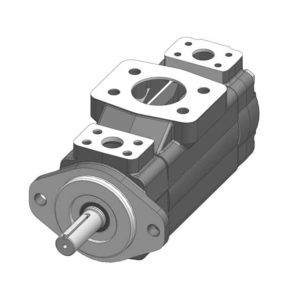

Dual Flow Pumps

6 products

-

Single Flow Pumps

5 products

-

ATEX Approved Pumps

2 products

-

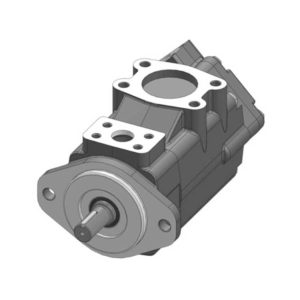

Axial Piston Pumps

97 products

-

Axial Piston Pumps - Bent Axis

23 products

-

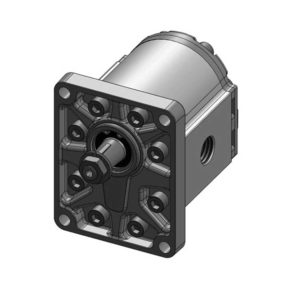

Gear Pumps - External

165 products

-

Gear Pumps - Internal

22 products

-

Gerotor Pumps

3 products

-

GOLD CUP Pumps

14 products

-

Hand Pumps

11 products

-

Radial Piston Pumps

5 products

-

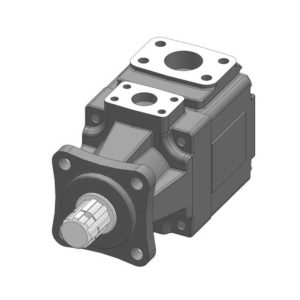

Vane Pumps

42 products