The world-famous Royal Shakespeare Company might be used to their performances raising the roof, but it came to Hydraulics Online when it needed to be able to lift the stage…

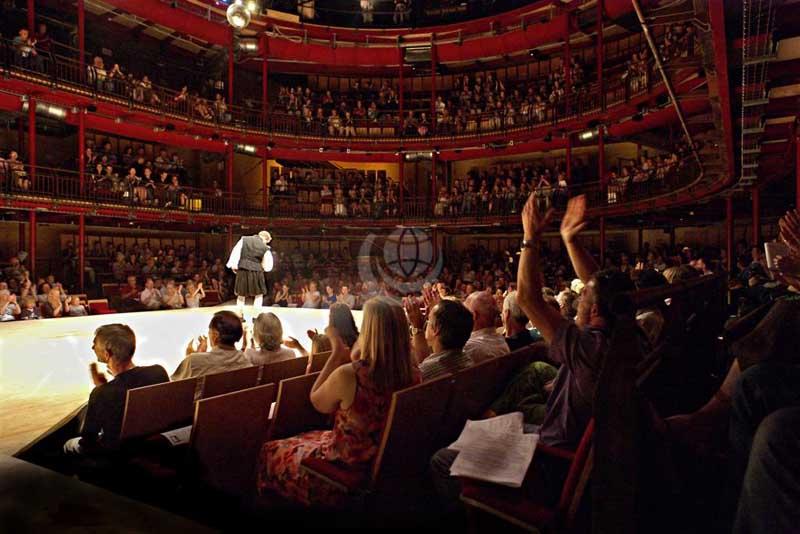

The Royal Shakespeare Company’s Stratford-upon-Avon theatres play host to more than one million visitors each year – all drawn by its breath-taking family Christmas shows, innovative productions and workshops and the finest theatre productions of Shakespeare’s plays in the world.

Nobody could beat Hydraulics Online on price. (Gill Leefe, Control Systems Engineer, RSC.)

When the Royal Shakespeare Company staged Wendy and Peter Pan in its Royal Shakespeare Theatre in Stratford-upon-Avon, the whole team wanted to create a magical, beautiful experience for its family audiences.

Control Panel Systems for Heavy Lifting

Gill Leefe is Control Systems Engineer at the RSC in Stratford and was responsible for the control of the hydraulic system. Gill says: “There are important safety considerations when using hydraulic equipment and we have to be very careful, but they can be very useful in the theatre. We do have our own mains power system for the hydraulics and we make use of them when there are big, heavy things to move.”

For the production of Wendy and Peter Pan, the hydraulics were used to move large pieces of set, to startling effect.

Gill explains: “While Wendy is looking for the lost boys, the stage begins to rise, revealing Tinkerbell underneath. In the space the elevated stage creates, another piece of set rises to reveal the hidey-hole where the Lost Boys live and eleven boys dancing on the set.”

The two separate controllers were linked together to a central control panel. With one actor strapped to one element of the moving set and more rising with the second moving element of the set, it was vital that the hydraulic systems were in perfect working order and fully safety tested.

“Sometimes I operated that show,” says Gill, “and from where I sat I could see the front row of kids. When the stage began to lift up they would jump out of their seats, wondering what was going on. Then I could see the expressions of wonder on their faces; they were really excited. It was an absolutely brilliant moment.”

The equipment was reused in 2016 at London’s Barbican theatre in the production of King Lear starring Antony Sher – following which it was returned to Stratford-upon-Avon for reconditioning. Gill needed to replace a Parker dual driver multi-function proportional valve, and a quick online search showed that Hydraulics Online could help.

Great Service

“The team at Hydraulics Online were really efficient and friendly,” says Gill.

Sometimes we are not the easiest people to deal with because we can generate a lot of paperwork; taking on a new supplier can be a lengthy process for us, but Hydraulics Online worked very quickly and made it really easy for us.

(Gill Leefe, Control Systems Engineer, RSC.)

The pain of setting up a new supplier did prompt Gill to check with existing suppliers as to whether they could supply a suitable part. Gill explains: “I did call around looking for alternative quotes, but nobody could match Hydraulics Online on price.”

The control panel valve arrived in good time, ahead of the stated lead time, and Gill says she was very impressed with the service: “Hydraulics Online were very efficient and pleasant to deal with throughout and their price is the best. I will definitely be using Hydraulics Online again and would recommend them,” she comments.

The equipment is now being used in the theatre, helping to bring some future RSC magic to audiences for years to come.

Whether, like Gill, you need hydraulic equipment to create spectacular public performances, or you have a more low profile problem to solve… we’re here.