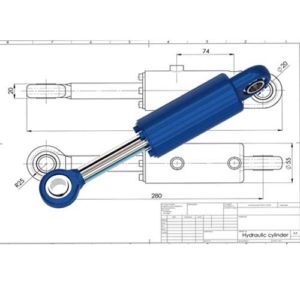

Choose from the largest selection of standard hydraulic cylinders in the UK. In addition, we offer bespoke cylinders tailored to your specific needs.

For tailored made hydraulic cylinders and solutions to suit your own specific application and operating parameters, simply complete our Bespoke Cylinder Design Form.

We also offer a comprehensive repair and refurbishment service too – recognising that this can often be quicker and cheaper than sourcing new equipment. Our service includes a free assessment where we will strip down your faulty unit and fully diagnose the extent of repair work needed.

We update our product catalogue daily – please contact us for details, advice and configuration options, if you cannot see the hydraulic cylinder that you need listed below.

-

Double-Acting Hydraulic Cylinders

19 products

-

Marine Hydraulic Cylinders

2 products

-

Mill Type Hydraulic Cylinders

3 products

-

Single-Acting Hydraulic Cylinders

26 products

-

Telescopic Hydraulic Cylinders

2 products

-

Tie Rod Hydraulic Cylinders

6 products

-

Welded Hydraulic Cylinders

3 products