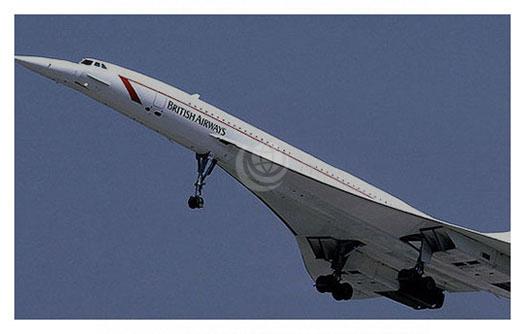

Under the Wings of Concorde G-BOAC

Jubilee celebration under the wings of Concorde G-BOAC 2nd March 2019 marked the 50th anniversary of the first Concorde flight taking off from Toulouse in France in 1969. It was a day Hydraulics Online and thousands of other Concorde enthusiasts had...