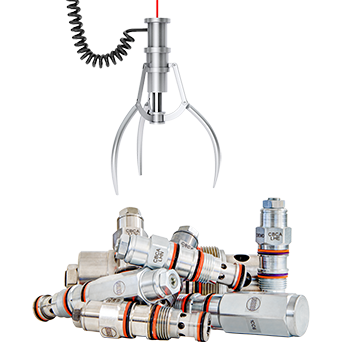

Sun Hydraulics is a leading designer and manufacturer of high performance screw-in hydraulic cartridge valves and manifolds. Their products control force, speed and motion and are integral components in fluid power systems for industrial and mobile applications.

They offer standard manifolds in nearly limitless variety; custom manifolds can also be designed to meet specific customer requirements. Their cartridge valve products are available in up to 5 sizes (capacities), are capable of handling flows up to 400 gallons per minute, and operate at pressures up to 5,000 pounds per square inch.

Sun sell their products globally, primarily through independent distributors, to diverse markets of mobile and industrial equipment and machinery manufacturers. They offer products that advance customers’ businesses – improving the safety and performance of the machinery in which they are used. From the outset, Sun have set the standard for the screw-in hydraulic cartridge valve industry.

Sun’s floating cartridge construction and cavity design approach allows products to operate precisely and reliably at higher pressures and flow rates in the most demanding applications. The generous porting area, coupled with their manifold design and construction techniques, result in integrated packages that can be up to 50% smaller than competitive offerings.

Please contact us for further technical guidance or if you cannot see the hydraulic valves and equipment that you need – we’ll be happy to help!

Sun Hydraulics Product Range

Sun Hydraulics Cavity Plugs

Sun Hydraulics cavity plugs allow for the removal of cartridge valves from a circuit while still maintaining the integrity of the…

View

Sun Hydraulics Directional Check Valves

Sun Hydraulics directional check valves feature high flow capacity relative to their small physical size. These Sun check valves can…

View

Sun Hydraulics Directional Control Valves

Sun Hydraulics directional control valves, or balanced and unbalanced logic switching valves, can be used for a variety of directional…

View

Sun Hydraulics Directional Shuttle Valves

Sun Hydraulics directional shuttle valves are available as two-, three- and four-port shuttle cartridges. All Sun shuttle cartridges operate at…

View

Sun Hydraulics Flow Control Valves

Sun Hydraulics flow control valves are available as 2-, 3- and 4-port flow control cartridges for metering and flow regulation.…

View

Sun Hydraulics Flow Divider Valves

Sun Hydraulics flow divider and flow divider / combiner valves are sliding spool devices that are used to split or…

View

Sun Hydraulics Load Control Valves

Sun Hydraulics load control, load reactive valves complement other existing motion control products. They share the same cavities as CB**,…

View

Sun Hydraulics Logic Valves

The range of Sun Hydraulics logic valves (logic elements) offers a broad variety of balanced and unbalanced logic switching valves…

View

Sun Hydraulics Manifolds

The Sun Hydraulics manifolds range includes line mount, sandwich, motor mount, subplate, bar manifold and gasket mount All sun manifolds…

View

Sun Hydraulics Pilot-to-Open Check Valve

Sun Hydraulics pilot-to-open check valves are non-modulating, on-off devices used for holding a load or actuator in position. They can…

View

Sun Hydraulics Pressure Control Reducing Valves

Sun Hydraulics pressure control reducing valves are available in many different versions and can be conveniently applied using many mounting…

View

Sun Hydraulics Pressure Control Relief Valves

Sun Hydraulics pressure control relief valves are pressure limiting and pressure regulating relief valves that are suited to many mounting…

View

Sun Hydraulics Pressure Control Sequence Valves

Sun Hydraulics pressure control sequence valves are similar to relief cartridges except that the pilot is separately drained so that…

View

Sun Hydraulics Solenoid Operated Valves

Sun Hydraulics solenoid operated valves are offered in full-flow or pilot-flow versions. Full flow versions are available in 2-way, 3-way…

ViewGet in Touch

"*" indicates required fields